Unlocking Sustainable Growth: How Regulatory Clarity Will Transform Manufacturing?

AI in Manufacturing: Enhancing Efficiency, Reducing Downtime, and Driving Growth

In 2025, AI agents will revolutionize manufacturing with predictive maintenance and autonomous decision-making, optimizing processes and reducing downtime. The transformative impact of AI agents in manufacturing is reshaping the industry by enhancing efficiency, precision, and adaptability. AI agents are revolutionizing industrial operations through advanced data analytics, predictive maintenance, and autonomous decision-making.

These intelligent systems enable manufacturers to optimize manufacturing processes, reduce downtime, and improve product quality. As the technological landscape rapidly evolves, it is crucial for manufacturers to embrace AI-driven innovations to remain competitive and meet the demands of a dynamic market. Adapting to these advancements not only ensures operational excellence but also paves the way for sustainable growth and innovation in the manufacturing sector.

AI technologies, including machine learning and generative AI, are being embedded into manufacturing systems to provide data-driven insights and identify patterns that were previously undetectable. This integration allows for real-time monitoring and adjustments, ensuring that manufacturing processes are continuously optimized. The use of AI models and algorithms helps in predicting equipment health and scheduling maintenance before failures occur, thus reducing downtime and enhancing overall productivity.

Regulatory Clarity Will Unlock Growth in Sustainable Manufacturing Operations

Increasing regulations around sustainability and environmental impact will force manufacturers to adapt their processes and materials. In some regions, foundational laws are just beginning to be implemented to enable green hydrogen or offshore wind investments. In the year ahead, we expect these regulatory barriers to be clear, paving the way for increased investments and a rise in new projects. As a result, manufacturers will need to adopt knowledge work automation solutions to scale and standardize operations for greater efficiency and repeatability. The manufacturing industry must also focus on quality control and the integration of machine learning models to enhance production standards.

Regulatory clarity will provide manufacturers with the confidence to invest in new technologies and processes that support sustainable growth. By adopting AI-driven solutions, manufacturers can achieve greater transparency and traceability in their operations, ensuring compliance with environmental regulations. This shift towards sustainable manufacturing will not only benefit the environment but also create new opportunities for innovation and market growth. As manufacturers work closely with regulators and industry stakeholders, they will be better positioned to navigate the evolving landscape and drive long-term success.

AI Integration Will Require Focus on Foundational Systems in Manufacturing Companies’ Digital Transformation Efforts

The integration of advanced technologies like IoT, AI, and automation into existing systems will remain a significant challenge in digital transformation for manufacturing companies. Currently, we find ourselves in the upward phase of the AI hype cycle, where expectations may be running ahead of practical reality. In the year ahead, businesses will come to realize the importance of strengthening foundational systems and integrations, as these will support AI agents in the same way they empower human workers. While routine task automation will free employees to focus on more strategic work, we can also expect substantial advancements in AI capabilities, bringing about real, transformative change.

To successfully integrate AI technologies, manufacturers must prioritize the development of robust data infrastructure and cybersecurity measures. Ensuring the integrity and security of manufacturing data is critical for the effective deployment of AI systems. Additionally, manufacturers should invest in training programs to equip their workforce with the skills needed to manage and operate AI-driven technologies. By fostering a culture of continuous learning and innovation, manufacturers can stay ahead of the curve and capitalize on the benefits of AI adoption.

Human-Machine Collaboration: A Necessity in the Future for the Manufacturing Industry

As AI and automation become more prevalent in manufacturing, collaboration between humans and machines will be essential. Rather than replacing human workers, AI can augment their capabilities, allowing them to focus on more complex and strategic tasks. This collaboration will require a shift in workforce training and development, emphasizing the importance of digital literacy and continuous learning. By fostering a culture of innovation and adaptability, manufacturers can ensure that their workforce remains competitive in an increasingly automated industry.

AI Agents Will Revolutionize the Future of Manufacturing Operations

The transformative impact of AI agents in manufacturing is reshaping the industry by enhancing efficiency, precision, and adaptability. AI agents are revolutionizing industrial operations through advanced data analytics, predictive maintenance, and autonomous decision-making. These intelligent systems enable manufacturers to optimize manufacturing processes, reduce downtime, and improve product quality.

Adapting to these advancements not only ensures operational excellence but also paves the way for sustainable growth and innovation in the manufacturing sector.

AI agents are also playing a key role in enhancing supply chain management and overall productivity. By leveraging AI algorithms, manufacturers can optimize their supply chain operations, ensuring timely delivery of essential products and minimizing disruptions. AI-driven insights enable manufacturers to make data-driven decisions, improving their responsiveness to market trends and customer demands. As AI technologies continue to evolve, we can expect even greater advancements in manufacturing efficiency and innovation.

The Importance of Cybersecurity and AI in Manufacturing

With the increasing integration of AI and IoT in manufacturing, cybersecurity has become a critical concern. Protecting sensitive data and ensuring the integrity of connected systems is essential to prevent disruptions and maintain trust. Manufacturers must invest in robust cybersecurity measures, including encryption, access controls, and regular security audits. Additionally, adopting a proactive approach to cybersecurity, such as implementing AI-driven threat detection and response systems, can help mitigate risks and safeguard operations.

Manufacturing Jobs Will Evolve with the Adoption of AI

With the integration of AI in manufacturing, job roles are expected to evolve significantly by 2025. As AI takes over repetitive and manual tasks, there will be a greater demand for high-skill roles such as AI specialists, data analysts, and robotics engineers. Workers will need to develop new skills to manage and maintain AI systems, focusing on strategic and creative tasks. AI will foster more collaborative work environments, necessitating strong communication and teamwork skills. The rapid pace of AI advancements will require continuous learning and upskilling to stay relevant. Overall, this evolution will lead to a more skilled, efficient, and collaborative workforce.

The adoption of AI in manufacturing will also create new opportunities for career growth and development. Manufacturing engineers will play a crucial role in designing and implementing AI-driven solutions, while data scientists will be responsible for analyzing manufacturing data and developing machine learning models. As AI technologies become more integrated into daily operations, workers will need to adapt to new ways of working and embrace a culture of innovation. This shift will ultimately lead to a more dynamic and resilient manufacturing workforce, capable of driving the industry forward.

The Future of Customization and Personalization

AI is enabling a new era of customization and personalization in manufacturing. By analyzing consumer data and preferences, manufacturers can create tailored products that meet individual needs. This shift towards mass customization requires flexible manufacturing systems that can quickly adapt to changing demands. AI-driven production planning and scheduling can help manufacturers achieve this flexibility, ensuring that they can deliver personalized products efficiently and cost-effectively.

Will Sustainable Growth Transform the Manufacturing Industry?

The integration of AI technologies in manufacturing is poised to revolutionize the industry by enhancing efficiency, reducing downtime, and driving sustainable growth. As manufacturers embrace AI-driven innovations and regulatory clarity, they will be able to optimize processes, improve product quality, and adapt to dynamic market demands. Strengthening foundational systems, ensuring robust data infrastructure, and prioritizing cybersecurity will be crucial for this transformation. Human-machine collaboration will augment human capabilities, enabling workers to focus on strategic tasks and foster a culture of continuous learning and innovation. Ultimately, AI adoption will lead to a more efficient, resilient, and innovative manufacturing sector, capable of driving long-term sustainable growth.

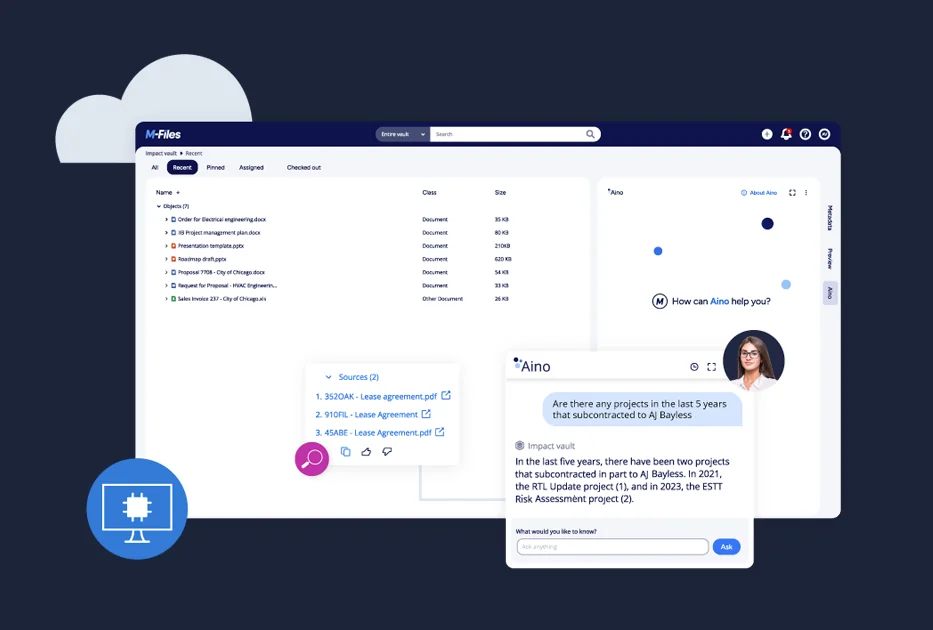

By Samppa Lahtinen, Senior Manager of Industry Solutions at M-Files